Exploring the Latest Innovations in Electronic Drainage Valves

Release time:

Mar 25,2025

In recent years, the industrial sector has witnessed significant advancements in the design and functionality of electronic drainage valves. These innovative devices play a crucial role in managing fluid flow and ensuring efficient drainage in various applications. The newest electronic drainage valves come equipped with cutting-edge technology that enhances their performance, reliability, and ease of use.

One of the primary advantages of the newest electronic drainage valves is their ability to provide precise control over fluid drainage. Unlike traditional mechanical valves, electronic versions utilize sensors and actuators to respond to real-time data, allowing for accurate flow regulation. This degree of control is particularly beneficial in environments where the composition of fluids can vary, ensuring that the system operates optimally under various conditions.

Moreover, the newest electronic drainage valves often feature integrated smart technology, enabling remote monitoring and control. This connectivity allows operators to track performance metrics and make adjustments from a distance, reducing the need for manual intervention and minimizing the risk of human error. Additionally, data collected from these systems can be analyzed to optimize operational efficiency, identify potential issues before they become critical, and enhance overall system reliability.

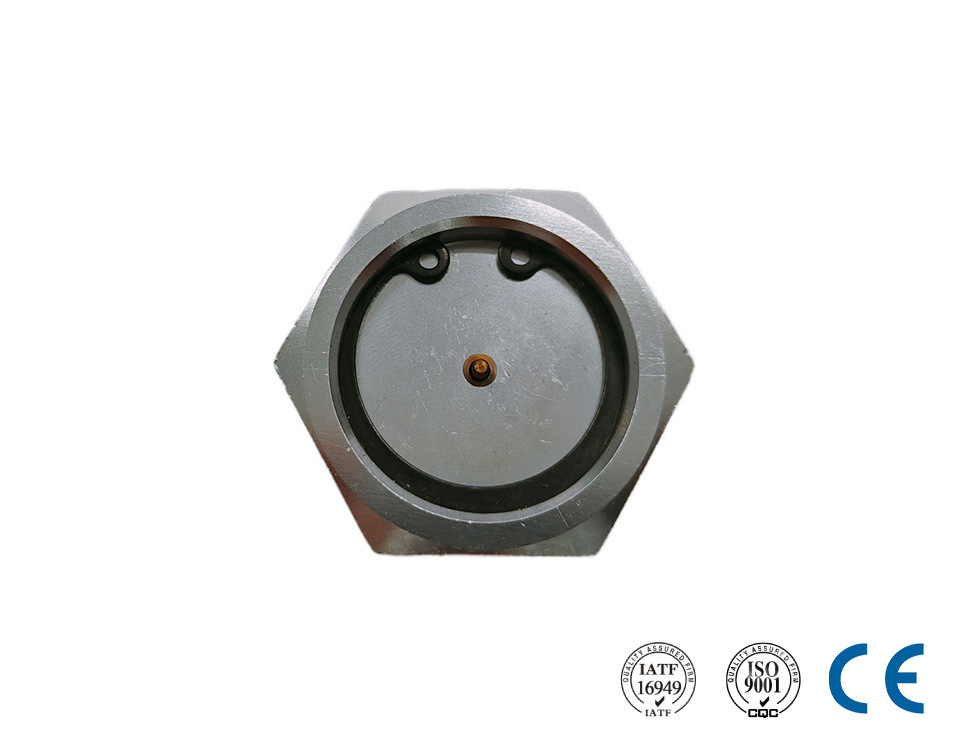

The materials used in the construction of the newest electronic drainage valves are also evolving. Manufacturers are increasingly utilizing corrosion-resistant materials that enhance durability and extend the lifespan of the valves. This is particularly important in industrial environments where exposure to harsh chemicals and fluctuating temperatures can degrade traditional valve components.

Another significant trend associated with the newest electronic drainage valves is their energy efficiency. Many of these valves are designed to minimize power consumption during operation, contributing to reduced operational costs and lower environmental impact. As sustainability becomes a priority in industrial operations, the energy-efficient design of electronic drainage valves aligns with these initiatives.

Furthermore, ease of installation and maintenance is a key focus for manufacturers. The newest electronic drainage valves are designed to be user-friendly, often featuring modular designs that simplify the installation process. Maintenance is also streamlined, with many valves offering self-diagnostic capabilities that alert users to potential maintenance needs before they lead to failures.

In conclusion, the newest electronic drainage valves represent a significant advancement in the field of industrial fluid management. Their precise control, smart technology integration, durable materials, energy efficiency, and user-friendly designs make them invaluable assets in any industrial setting. As industries continue to evolve, adopting these innovative solutions will be essential for staying competitive and achieving operational excellence.

Related Blog

Share